เครื่องทำลมแห้งแบบใช้เม็ดสาร (TRIDENT)

โทรศัพท์: 02 4525901

แฟกซ์: 02 4525902

มือถือ: 086 511 7511

เครื่องทำลมแห้งแบบใช้เม็ดสาร (TRIDENT)

เครื่องทำลมแห้งแบบใช้เม็ดสาร (TRIDENT)

เครื่องทำลมแห้งแบบใช้เม็ดสาร (TRIDENT) Heatless Desiccant Dryers - DP SeriesDesigned and tested to provide 100% clean, dry, oil-free compressed air at -40°c

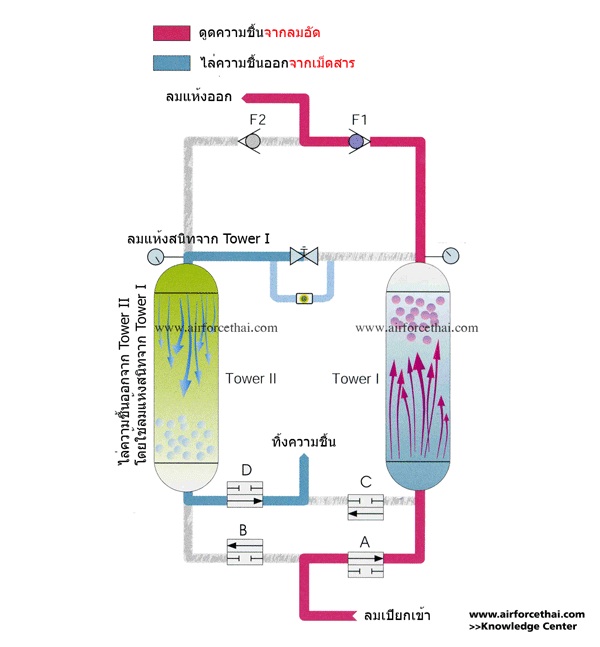

Heatless Desiccant Dryers - DP SeriesDesigned and tested to provide 100% clean, dry, oil-free compressed air at -40°c atmospheric dew point, to safeguard your valuable pneumatic equipment.Trident Dryers are available in 19 models to suit your requirement. They work with pressures from 4 kg/cm2(g) to 70 kg/cm2(g) and flow upto 1920 m3/hr.Prefilteration The moisture laden compressed air passes through the pre filter. Here moisture load is reduced through coalesence. Condensation is removed through the drain valve ADV1. At the oil filter (2) oil vapors are removed completely, small levels of oil/water condensation are purged through the valve ADV2. Compressed air is then passed through a 3 way valve into Tower.Drying The Towers are filled with Activated Alumina as desiccant (Molecular sieve available as option). When air passes through Tower 1 which consists of "DRY" Dessicant, it gets completely dried, and passes through check valve and After Filter(3). At the after filter, Desiccant fines are removed. Therefore dry compressed air passes out at the outlet.Regeneration Regeneration takes place in 2 stages a) De-pressurisation b) By passing Dry air. Tower II consists of fully moist desiccant at pressure. This is suddenly De-pressurised by opening the purge valve. Water molecules weep out of the desiccant and appear on the surface. "Super Dry" purge air passes through the Regeneration "Nozzle" and the desiccant bed thereby completely carrying away the water molecules. Tower 2 gets regenerated and is ready for the next drying cycle.

#จำหน่ายเครื่องปั๊มลม #จำหน่ายปั๊มลมสกรู #เครื่องปั๊มลม #Aircompressor #เครื่องปั๊มลมราคาถูก #ปั๊มลม #screwaircompressor #ปั๊มลมRICHTRCH #ปั๊มลมสกรู #ปั๊มลมราคาถูก #ปั๊มลมคุณภาพ #ซ่อมปั๊มลม #โอเวอร์ฮอร์นปั๊มลม #ปั๊มลมที่ดีที่สุด #overhaulscrewaircompressor #ปั๊มลมอุตสาหกรรม #ปั๊มลมราคาถูก #Airdryer #เครื่องทําลมแห้ง #Mainlinefilter #ไส้กรองปั๊มลม #ถังลม #ถังพักลม #Airtank #ขายถังลม #อะไหล่ปั๊มลม #น้ำมันปั๊มลม #Airfilter #เดินท่อลม #จําหน่ายปั๊มลม

แฟกซ์: 02 4525902

มือถือ: 086 511 7511